Impact wrenches are one of the most important tools if your job is fastening and removing stubborn nuts and bolts on a daily basis.

Knowing its importance, it’s easy to understand why it’s essential to lubricate and maintain it properly.

Now, don’t roll your eyes; proper care and attention will keep your wrench in tip-top shape, ensuring it’s always ready for action.

So, let’s get down to business and learn about how to join an impact wrench so you don’t have to regret not doing it later.

Tools and Materials Needed

Before you dive into oiling your impact wrench, you’ll need to gather some tools and materials to make sure everything goes as smooth as butter.

Remember, some impact wrenches use grease for lubrication, while others use oil.

Let’s go ahead and break down what you’ll need:

- High-Quality Air Tool Oil/Grease: Now, don’t you go cheap on me here. Your impact wrench deserves the best of the best. Normally, that means opting for a 20 or 30 weight oil, which is recommended by most manufacturers. And if you’re unsure, just check your owner’s manual to make sure.

- Clean Cloth or Rag: Let’s face it, this can get messy. You’ll want something to wipe off any excess oil, and maybe even clean up a little dirt.

- Funnel or Dropper: Trust me on this one, you don’t want oil all over the place. A funnel or dropper will help you get that liquid gold exactly where it needs to go. For a small investment of less than 10 bucks, you’ll save yourself from making a mess.

- Protective Gloves: Let’s keep those hands clean and protected while we’re working with oil, shall we? Otherwise, you run the risk of skin irritation, slipping tools, or worse yet, an embarrassing story to tell your buddies.

So, gear up and get ready to show your impact wrench the love and care it deserves. It’ll thank you by giving you years of reliable service.

Step-by-Step Guide on Oiling an Impact Wrench

As explained, oiling an impact wrench is key to extending its life and keeping it running like in good condition.

There are many ways to oil an impact wrench which could make things confussing, but I’ve got your back.

These, I believe, are the most efficient steps to make sure you oil your impact wrench properly:

Step 1: Prepare Your Workspace

Clear a spot on your workbench, lay down some old newspaper, and put on those protective gloves. It’s about to get real, and we don’t want any spills or messes, now do we?

Step 2: Disconnect the Air Supply

Safety first, my friends!

Disconnect your impact wrench from the air supply or power source to avoid any sudden surprises like accidental activation which could lead to serious injuries.

Step 3: Locate the Oil Inlet

Find the oil inlet on your impact wrench, which is usually a small hole or port on the tool’s body, this is where the oil will go.

If you’re having trouble, consult your owner’s manual, or do a quick search online.

Step 4: Add Oil

Now it’s time to add the good stuff.

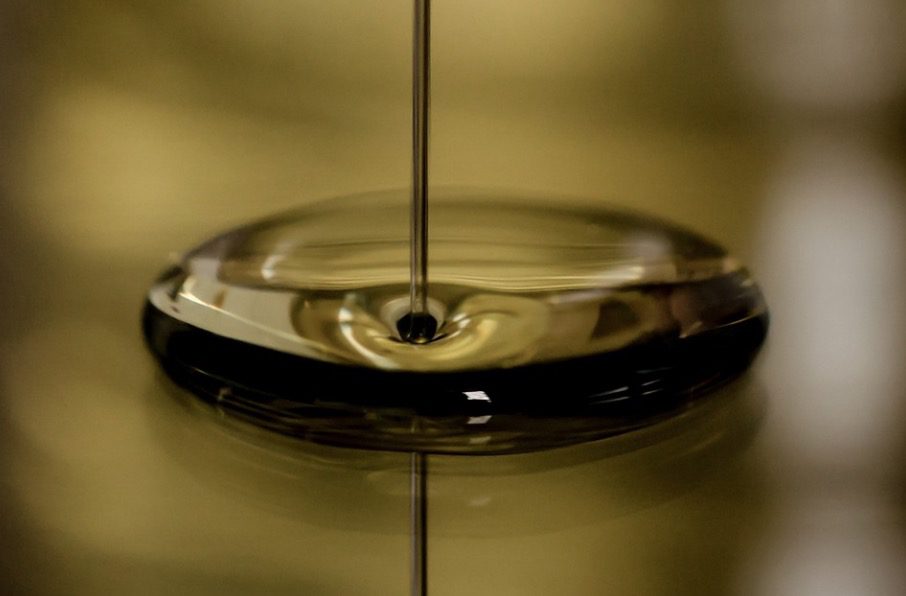

Grab your high-quality air tool oil (normally it’s 20 or 30W oil), and your funnel or dropper and carefully pour the oil into the inlet.

Normally, you should put about a tablespoon of oil, but that depends on the impact wrench’s model (which is why, again, I’d tell you to consult the owner’s manual of your impact wrench).

Step 5: Wipe Excess Oil

Take your clean cloth or rag and gently wipe away any excess oil around the inlet, ensuring a clean and tidy workspace.

Step 6: Reconnect the Air Supply

Once you’ve finished oiling, reconnect your impact wrench to the air supply or power source. Give it a quick test run to make sure everything is working smoothly, and you’re good to go!

Step-by-Step Guide on Greasing an Impact Wrench

Some impact wrenches prefer grease over oil for lubrication thanks to its thicker consistency and ability to maintain lubrication, especially when working with heavy-duty applications.

The things is that greasing your impact wrench is a bit more hands-on than oiling, but don’t worry, I’ve got you covered.

Here’s the best way to grease your impact wrench to keep it running like a well-oiled machine (pun intended):

Step 1: Gather Your Tools

Make sure you have everything you need: a high-quality grease, a clean rag, and, of course, those protective gloves to make sure your hands stay clean and safe from any irritants.

Step 2: Remove the Cover and Hammer Mechanism

Carefully take off the housing cover of your impact wrench, exposing the hammer mechanism.

The aim here is to be able to access the vital components that need greasing.

Remember, it’s like performing surgery, but on a tool. So be gentle, and take your time.

Step 3: Get Greasy

Grab a dab of grease on your finger (with the gloves on) and apply it all over the hammer mechanism and anvil.

But listen up, don’t go overboard as too much grease can actually hinder the performance of your impact wrench by causing unnecessary resistance and reducing efficiency.

Step 4: Put It Back Together

Now that everything is nicely greased up, it’s time to reassemble the housing.

Make sure everything is lined up and snug, just like the day you brought it home. Again, take your time here.

Step 5: Test Run

Once everything is back in place, connect your impact wrench to its power source and give it a whirl. Run it forward and backward to ensure everything is running smoothly and that your tool is ready to tackle whatever job comes its way.

Tips and Tricks for Proper Oiling

I’ve got some insider tips and tricks to make sure you’re oiling your impact wrench efficiently, which is essential to keeping it running smoothly and extending its lifespan.

Here are the tips:

- Stick to a Schedule: Make it a habit to oil your impact wrench every time you use it or at least once a week if you’re a frequent user. Your tool will thank you with years of loyal service.

- Don’t Overdo It: I know it’s tempting to douse your wrench in oil like it’s an extra-crispy French fry, but resist the urge. Too much oil can cause performance issues and even damage your tool. Stick to the recommended amount in your owner’s manual.

- Use the Right Oil: Not all oils are created equal. Make sure you’re using air tool oil or grease specifically designed for impact wrenches, normally it’s 20W or 30W oil. Your wrench deserves the best, so don’t settle for less.

- Keep It Clean: Before oiling, give your impact wrench a quick wipe down to remove any dirt or debris. Otherwise, you could end up trapping dirt inside the tool while oiling, which might lead to more problems down the road.

- Pay Attention to the Weather: If you’re working in extreme temperatures, you may need to adjust your oiling routine. Cold weather can thicken oil, while hot weather can thin it out. Consult your owner’s manual for any temperature-specific recommendations.

Frequently Asked Questions

What kind of oil for impact wrench?

When it comes to lubricating your trusty impact wrench, you should consult the tool’s owner’s manual as it will tell you exactly what oil you need.

In my experience, a top-of-the-line 20W or 30W oil should be your go-to choice for ensuring a smooth, long-lasting performance.

So, next time you’re tempted to grab that dusty bottle of generic oil from the back of the shelf, remember: your impact wrench could be seriously damaged.

Give it the lubrication it deserves, and it’ll keep serving you for years to come

What kind of grease for impact wrench?

When you need to grease your impact wrench, opt for a top-notch, heavy-duty grease that’s specifically formulated for air tools.

Look for one that’s resistant to heat and won’t break down easily, so it can keep your wrench running smoothly even under extreme conditions.

It’s all about treating your tools right, and they’ll return the favor with years of dependable service.