You’re probably here because you’ve heard the term “friction ring” and you’re curious to know what it’s all about.

Or maybe you’re just looking for ways to make your impact wrench even more efficient.

Whatever your reason, I’ve got you covered! In this article, I’ll break down what a friction ring is, how it works, and the benefits of using one on your impact wrench.

Let’s dive in.

What is a Friction Ring?

So you want to know what a friction ring is, huh? Well, you’ve come to the right place. I’ll break it down for you in the simplest way possible.

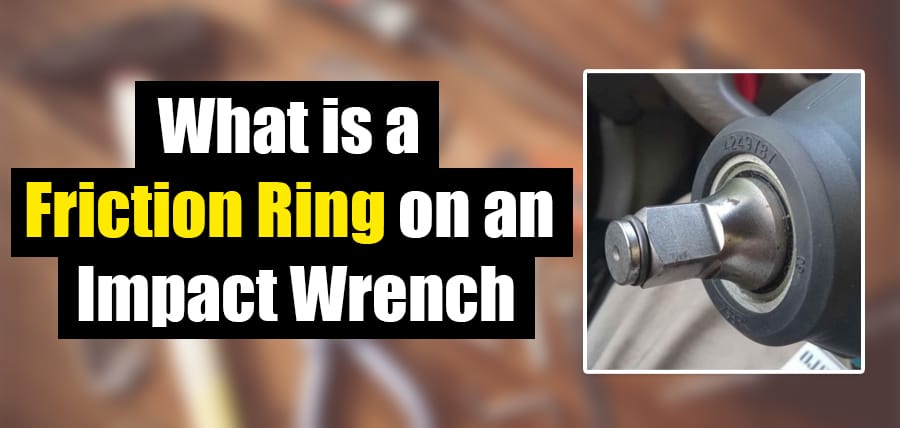

A friction ring, also known as a hog ring, is a small, circular component found on many impact wrenches, specifically around the anvil (you know, that square-ish part where the socket attaches).

Its primary purpose?

Keeping your impact sockets securely in place and making it a breeze to swap them out when needed. It’s a circular metal piece that fits snugly around the anvil of your impact wrench, providing the perfect amount of tension to keep your sockets right where they should be.

Without a friction ring, you’d be dealing with sockets slipping off, wobbling around, and making your job way harder than it needs to be.

Trust me, you don’t want that kind of chaos in your life.

How a Friction Ring Works

Now that you know what a friction ring is, let’s dive into the nitty-gritty of how it actually works.

So, the friction ring is this unassuming little metal hoop that hangs out on your impact wrench’s anvil so that when you slide a socket onto the anvil, the friction ring jumps into action, gripping the socket’s inner groove.

The magic here is all about tension: the friction ring’s got just enough tightness to hold that socket firmly in place, but not so much that you can’t easily swap it out when needed.

You might be wondering, “But how does it maintain that perfect tension?”

Well, my curious friend, the secret sauce lies in the material and design of the friction ring. It’s usually made of durable metal, like spring steel, and is designed to flex just enough to accommodate your socket but still provide a secure grip.

It’s a delicate balance, but it works like a charm.

Benefits of Using a Friction Ring on an Impact Wrench

Wondering why you should care about the benefits of using a friction ring on your impact wrench?

Well, here they are!

- Socket Security: The friction ring’s main job is to keep your socket securely attached to the anvil. Without it, you’d be dealing with loose sockets, which is a recipe for frustration and wasted time.

- Easy Socket Changes: When you’re working on a project, the last thing you want is to wrestle with a stubborn socket. With a friction ring in place, you can swap out sockets quickly and easily, keeping your workflow smooth and efficient.

- Reduced Wear and Tear: Friction rings help prevent excessive wear on the anvil and sockets. By holding the socket securely, the friction ring minimizes wobbling and ensures a snug fit, leading to a longer-lasting tool and sockets.

- Saves Time: Time is money, and friction rings save you time by allowing fast socket changes and reducing the chances of lost or dropped sockets.

- Versatility: Many impact wrenches with friction rings can accommodate a wide variety of socket sizes, giving you the flexibility to handle various tasks without needing multiple tools.

Friction Ring vs Pin Detent

Well, it’s time for a head-to-head battle between two heavyweight contenders in the world of impact wrench socket retention: the friction ring and the pin detent.

But before we jump into the ring and witness this epic showdown, let’s make sure we’ve got the basics covered on what’s what:

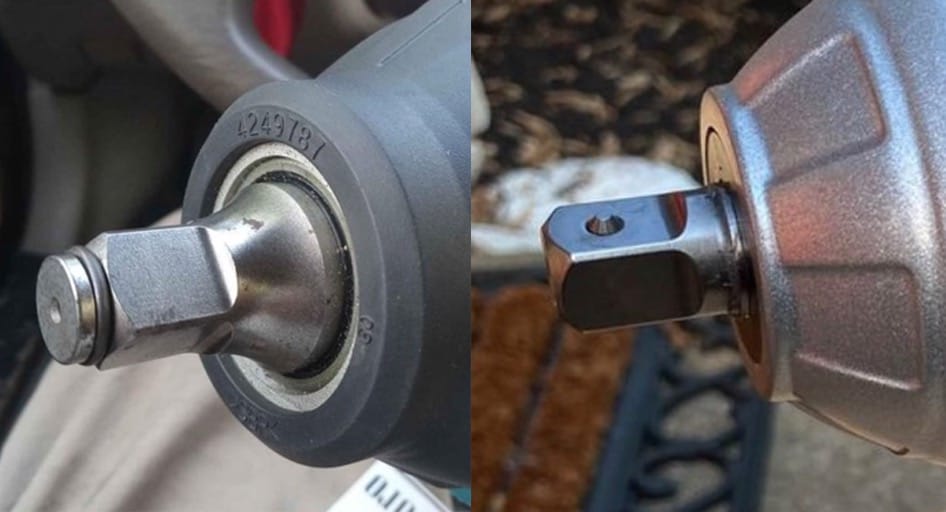

- Friction Ring (aka Hog Ring): It’s a circular metal component that fits around the anvil of your impact wrench, holding your sockets securely in place and making it easy to change them when needed.

- Pin Detent: Instead of a metal ring, the pin detent system uses a small steel ball bearing that fits into a hole or groove in the socket. When you slide the socket onto the anvil, the steel ball clicks into place, securing the socket. To release it, you need to press a release button or use a tool like a screwdriver to disengage the ball.

Round 1: Ease of Socket Changes

The friction ring is known for its quick and easy socket swaps. With a friction ring, you can slide your sockets on and off the anvil without any hassle, making it perfect for projects that require frequent socket changes.

The pin detent is a bit more stubborn. It provides a more secure grip, but that means you’ll need to put in extra effort (and sometimes use a tool) to remove a socket.

So, for ease of socket changes, the friction ring takes the round!

Round 2: Socket Security

The friction ring does a decent job holding your sockets in place, but when it comes to the ultimate socket security, the pin detent is the undisputed champion.

So why is the pin detent system so much more secure?

Well, it’s all about that little steel ball bearing.

When it clicks into place in the socket’s groove, it forms an incredibly strong bond that resists the forces trying to pull it apart.

On the other hand, the friction ring relies on the tension between the ring and the socket’s groove. While it does a fine job in most cases, it might not provide the same level of steadfastness as the pin detent, especially when dealing with high torque or extreme vibrations.

And with that, Round 2 goes to the pin detent!

Round 3: Versatility

Now let’s talk about versatility, my friends. When you’re working on various projects, you wouldn’t want to be bogged down by tools that can’t adapt to your needs, right?

In that context, friction rings play well with a whole bunch of socket sizes, making them the go-to choice for those who love flexibility.

Pin detents, on the other hand, can be a bit more particular as they might require specific sockets designed to work with the pin detent system, which can be a bit limiting when it comes to versatility.

So, when you need a tool that’s ready to roll with the punches and adapt to your ever-changing project needs, the friction ring comes out on top.

Round 4: Durability

You want a tool that’s not just a one-hit-wonder, but one that’ll stand the test of time and keep performing like a champ, right?

Well, that’s where the battle between friction rings and pin detents heats up.

Both anvil designs are pretty darn durable, but when it comes down to brass tacks, the pin detent has a bit of an edge as its design is built to withstand some serious abuse, making it perfect for heavy-duty applications where things can get a little rough and tumble.

Friction rings, while still strong and reliable, may eventually lose some of their tension over time.

Frequently Asked Question

What is a Makita friction ring?

Like other friction rings, Makita’s friction ring is there to secure your sockets and make changing them a breeze.

It works by providing just the right amount of tension around the anvil of the impact wrench, holding the socket firmly in place while still allowing for easy removal when needed.

So, if you’re a proud owner of a Makita impact wrench, you’ll want to have this handy-dandy friction ring on your tool to keep things running smoothly.

What is a friction ring made of?

Now, let’s talk materials.

Friction rings are typically made from hardened steel or metal alloy.

These materials are chosen for their durability, strength, and resistance to wear, ensuring that your friction ring can withstand the daily grind of heavy-duty work.

So, you can count on your trusty friction ring to keep your sockets secure and make your life easier, no matter how tough the job gets!